Option Libary

Your one-stop solution for perfect packaging.

Bringing tailor-made packaging solutions to businesses worldwide, W & G is a leading packaging manufacturer. Our global presence enables us to cater to diverse industries across the globe, providing customized packaging that meets your unique requirements. Leveraging our vast experience in collaborating with various sectors, we have thoughtfully curated a wide range of material options, carefully selected for their specific capabilities. Explore the convenience of our meticulously assembled library, where you’ll discover everything necessary to attain the ideal packaging solution.

Paperboard

A versatile single-layer paper material suitable for a wide range of applications.

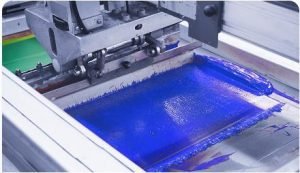

Print Methods

Various printing techniques are accessible to help you achieve your distinctive appearance.

Inks

Choose from a variety of inks to cater to your specific requirements, including eco-friendliness, food safety, or unique preferences.

|

|

|

|

Water-based InksPrinting inks that use water as the primary solvent instead of chemicals, making them eco-friendly and safe for various applications. | Soy/Vegetable Based InksEco-friendly printing inks derived from renewable resources like soybeans, reducing environmental impact compared to traditional petroleum-based inks. | PantoneA standardized color matching system used in design and printing to ensure consistent and accurate color reproduction. | Pantone MetallicA color system that includes metallic shades, used for design and printing to achieve metallic and shiny effects. |

Coating

Enhance your packaging with printed coatings for added protection or a polished finish.

|  |  |  |

Aqueous CoatingA water-based protective layer applied to printed materials for added durability, improved appearance, and resistance to scuffs. | UV coatingA protective finish applied to printed materials using ultraviolet light to create a glossy, durable, and eye-catching surface. | Spot Gloss UVA printing technique that adds a glossy and raised coating to specific areas for a shiny, tactile effect.” | Soft Touch CoatingA finishing technique that creates a velvety, tactile feel on surfaces, enhances aesthetics and provides a luxurious texture. |

| |||

VarnishA clear protective coating applied to surfaces, such as wood or printed materials, to enhance appearance and durability. |

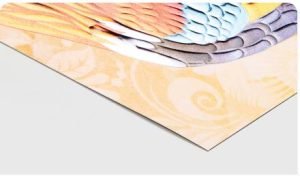

Lamination

Enhance the protection and aesthetics of your packaging.

|  |  | |

LaminationA process of bonding two or more layers of material together, often involving a plastic film, to enhance durability, protection, and appearance, commonly used in documents, cards, and packaging. | Anti-scratch laminationA protective coating applied to surfaces to prevent scratches, preserving the material’s appearance and integrity by making it more resistant to damage from abrasion and friction. | Soft touch or Silk LaminationA finishing technique for printed materials that creates a smooth, velvety texture, enhancing both tactile and visual appeal while adding durability and elegance. |

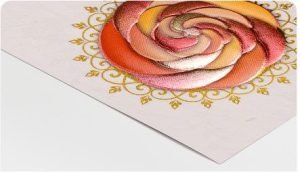

Special Options

Enhanced choices for enhancing your packaging.

|  |  |  |

Hot Foil StampingA printing technique that uses heat, pressure, and metallic foil to create shiny and decorative designs or text on various surfaces, adding elegance and sophistication to printed materials. | Cold Foil PrintingA printing technique that applies a thin layer of metallic foil to printed materials without the need for heat, adding a decorative and reflective finish to designs. | Blind EmbossingA printing technique where a design or pattern is raised on paper or other materials without adding ink or foil, creating a tactile and visually striking effect. | Blind debossingA print finishing technique where a design or pattern is pressed into paper or another material without using ink or foil, creating a tactile, three-dimensional effect. |

|  |  | |

Registered EmbossingA printing technique where an image or pattern is raised on paper, aligning perfectly with printed elements. It enhances texture and design precision in various applications like packaging and stationery. | Combination EmbossingA decorative technique that involves using multiple embossing styles (such as blind, foil, and sculpted embossing) on a single surface to create intricate and textured designs for print materials. | Window PatchingA packaging technique where a transparent plastic or film window is added to a product’s packaging to display its contents while protecting them and adding visual appeal. |

Paper Bag Handles

Handles for paper bags are crafted from a combination of organic and inorganic materials, serving as their primary construction components.

|

|

|

|

Cotton HandleA fabric or textile that mimics the soft and smooth feel of cotton, providing a comfortable and pleasant touch to the material. | Flat Cotton HandleA flat, wide cotton strap or handle used on bags or other items, offering comfort and ease of carrying. | Nylon Rope HandleA handle made of durable nylon material, commonly used on bags, boxes, or other items for a sturdy and comfortable grip. | PP Twisted HandleMade from polypropylene material, twisted for added strength and grip, commonly used in retail and packaging for convenience and durability. |

| |||

Polycster Satin Ribbon HandleA type of decorative ribbon made from polyester fabric with a smooth and shiny surface, often used for embellishing gifts, crafts, and clothing |

|  |  | |

Twist Paper HandleA type of handle commonly used in paper bags, formed by twisting strips of paper to create a sturdy grip for carrying items. | Flat Paper HandleA thin, flat strip of paper attached to bags or packaging for carrying convenience, often used in retail, food service, or gift wrapping. | Die Cut HandleA pre-cut opening or hole in packaging materials, like bags or boxes, designed to make it easier to carry or hold the item inside. |

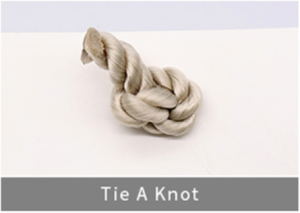

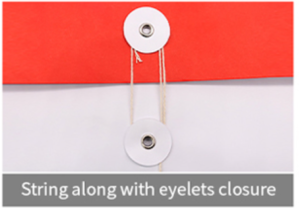

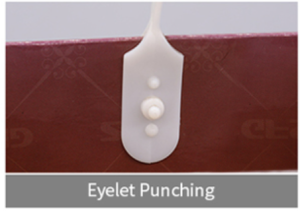

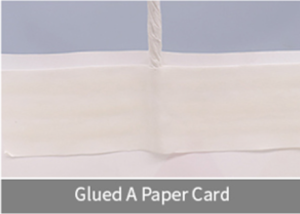

Connection for the Handle

Attachment point for the handle, facilitating carrying and control.

|  |  |  |

Ribbon Bowknot | Tie a Knot | Shoe Buckle | String Along with Eyelets Closure |

|  |  | |

Eyelet Punching | Glued a Paper Card | Embeded Handle |